Exploring the World of Industry Machines: Their Impact and Applications

The Evolution and Importance of Industry Machines

Industry machines have played a pivotal role in shaping the modern industrial landscape. From the early days of the Industrial Revolution, machines have been at the forefront of enhancing productivity and efficiency. They have transformed how industries operate, allowing for mass production and reducing the dependency on manual labor. This evolution has been marked by technological advancements, leading to more sophisticated and specialized machinery. Such developments have not only increased output but also improved the quality and consistency of products.

The importance of industry machines cannot be overstated. They are the backbone of manufacturing, enabling the production of goods at scales previously unimaginable. This capability has been crucial in meeting the growing demands of global populations and supporting economic growth. Furthermore, industry machines have facilitated advancements in other sectors, such as healthcare and transportation, by providing the necessary tools and components for innovation.

- Increased productivity and efficiency

- Reduction in manual labor

- Enhanced product quality and consistency

As we continue to advance technologically, the role of industry machines will only become more integral. Automation and artificial intelligence are set to revolutionize the capabilities of these machines, promising even greater efficiencies and innovations in the future.

Types of Industry Machines and Their Applications

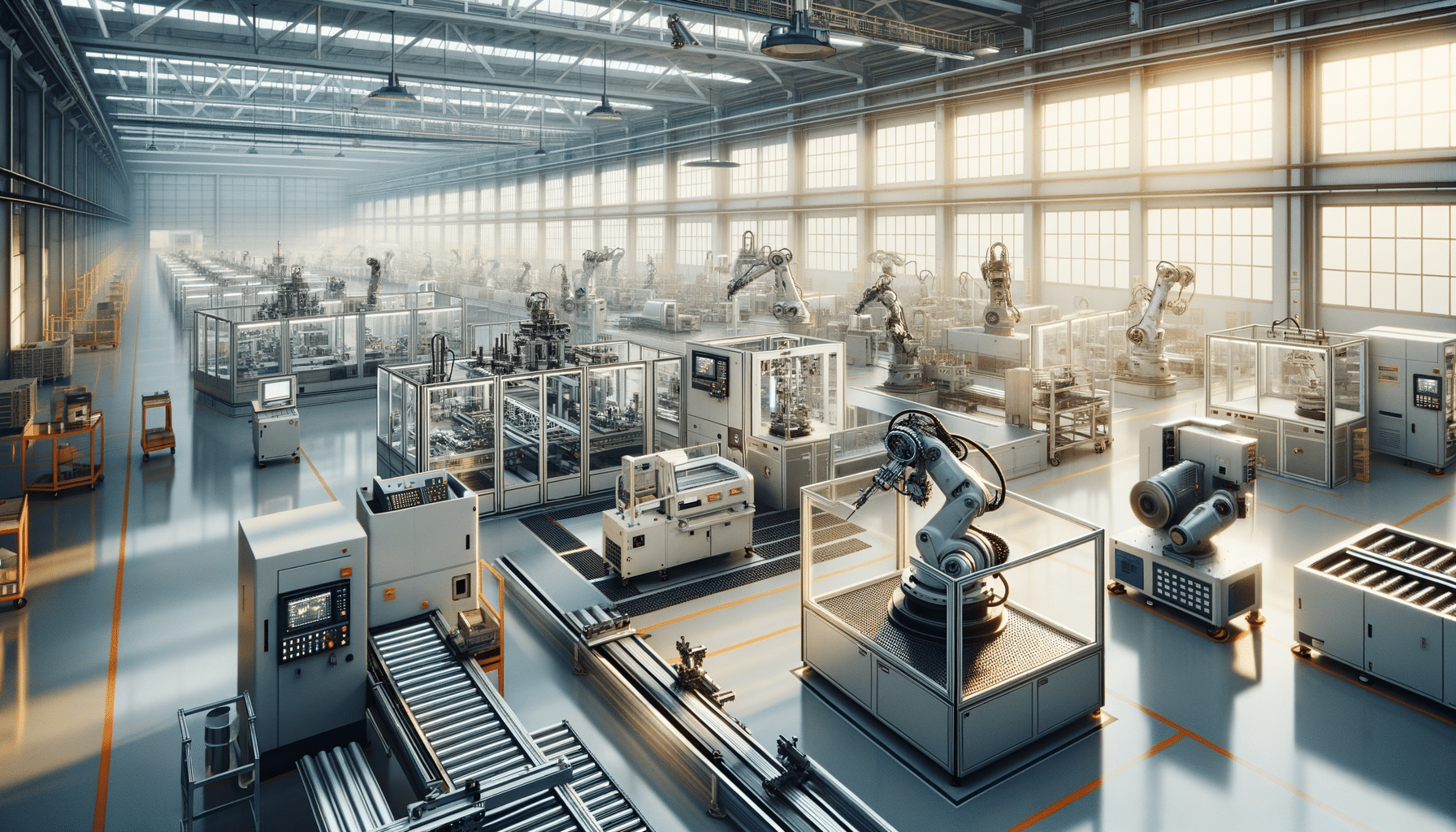

Industry machines come in a variety of forms, each designed to fulfill specific roles within different sectors. Some of the most common types include:

- CNC Machines: These are used for precise cutting, drilling, and milling, playing a crucial role in manufacturing components for various industries.

- Robotic Arms: Widely used in assembly lines, these machines enhance speed and accuracy, particularly in the automotive and electronics sectors.

- Printing Machines: Essential in the packaging industry, these machines produce labels, cartons, and other materials required for product packaging.

- Textile Machines: Responsible for the production of fabrics, these machines are vital in the fashion and home furnishings industries.

Each type of machine has a distinct application, tailored to meet the demands of specific industries. For example, CNC machines are indispensable in aerospace and automotive sectors, where precision is paramount. Similarly, robotic arms have transformed assembly lines, reducing human error and increasing throughput.

The versatility of industry machines is evident in their ability to adapt to various industrial needs. As technology progresses, we can expect these machines to become even more specialized, catering to niche markets and emerging industries.

The Impact of Industry Machines on Employment

The introduction and advancement of industry machines have significantly impacted employment patterns across the globe. On one hand, machines have replaced certain manual jobs, leading to concerns about unemployment. However, they have also created new opportunities, particularly in fields related to machine operation, maintenance, and programming.

While some traditional roles have diminished, the demand for skilled workers who can manage and operate these machines has increased. This shift has led to a greater emphasis on education and training, encouraging workers to acquire new skills relevant to the modern industrial environment. Moreover, the rise of automation and robotics has spawned new industries and job roles that didn’t exist a few decades ago.

It’s important to note that the relationship between machines and employment is complex. While machines can handle repetitive and dangerous tasks, they also free up human workers to focus on more creative and strategic roles. This dynamic has the potential to enhance job satisfaction and drive innovation within companies.

- Creation of new job opportunities in machine operation and maintenance

- Increased emphasis on education and skill development

- Shift towards more strategic and creative roles for human workers

Challenges and Considerations in Implementing Industry Machines

Implementing industry machines comes with its own set of challenges and considerations. One of the primary concerns is the initial cost of purchasing and installing these machines. This investment can be substantial, especially for small and medium-sized enterprises (SMEs) that may not have the capital to invest in high-tech machinery.

Another consideration is the integration of these machines into existing workflows. This process often requires significant changes to infrastructure and operations, which can be disruptive if not managed properly. Companies must also consider the ongoing costs of maintenance and the need for regular upgrades to keep machines running efficiently.

Furthermore, there is the challenge of ensuring that employees are adequately trained to operate these machines. This involves not only initial training but also continuous learning to keep up with technological advancements. Companies must invest in employee education to ensure that their workforce remains competent and confident in using new technology.

Despite these challenges, the benefits of implementing industry machines often outweigh the drawbacks. By enhancing productivity and reducing operational costs in the long term, these machines can provide a competitive edge in the rapidly evolving industrial landscape.

Future Trends in Industry Machines

The future of industry machines is set to be shaped by several key trends. One of the most significant is the integration of artificial intelligence (AI) and machine learning, which promises to enhance the capabilities of machines significantly. These technologies will enable machines to learn from data, improving their performance and efficiency over time.

Another trend is the increasing use of robotics and automation. As these technologies become more affordable and accessible, they are expected to be adopted by a wider range of industries. This shift will lead to more efficient production processes and higher quality products.

The rise of the Internet of Things (IoT) is also influencing the development of industry machines. IoT technology allows machines to communicate with each other and with central control systems, leading to smarter and more interconnected production environments. This connectivity can improve decision-making processes and streamline operations.

Finally, there is a growing focus on sustainability and reducing the environmental impact of industrial processes. Future industry machines are likely to be designed with energy efficiency and waste reduction in mind, aligning with global efforts to combat climate change.

- Integration of AI and machine learning

- Increased use of robotics and automation

- Adoption of IoT technology

- Focus on sustainability and environmental impact

These trends indicate that the future of industry machines is bright, with continued innovation and development expected to drive progress in various sectors.